Robot Assisted Manufacturing

Innovative technology

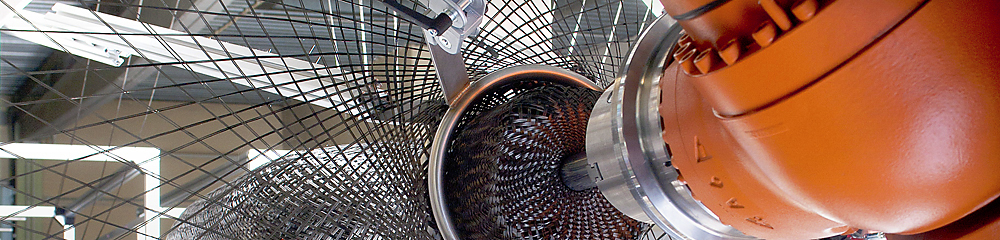

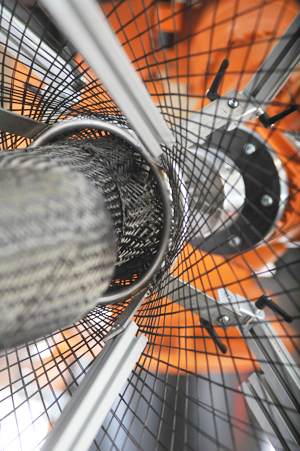

Our progress in developing new braiding technologies has made possible the creative placement of reinforcement fibres, particularly in the manufacture of preforms. This enables us to offer the possibility of developing bespoke product solutions, using ROBOT ASSISTED MANUFACTURING (RAM), in order to produce composites parts with optimised characteristics.

This technology provides excellent scope in overbraiding of different core types, geometries and bending radii. Permanent or removable core systems can be used; nearly everything is possible. Our maximum production capability is a length of 4.5m per part. Fibre angles along this length can be varied; multi-layer constructions are also possible. The possibilities are almost limitless in controlling fibre orientation in the component design. Fibre types available include carbon, glass, aramid and basalt; hybrid combinations of these fibres are also possible. Standard carbon types used are from 1K to 24K; special construction using fibre up to 50K can also be used in production.